Horizon Wall Panels

Artspan Inc. is looking for a select preferred installer network

If you would like to become a Artspan Preferred Installer, fill out the application form. We will review all applications and contact those who meet our criteria.

For more information, call: (204) 331-1800

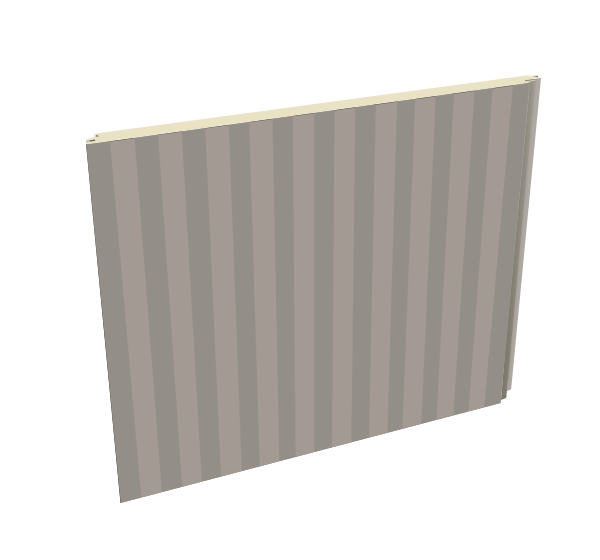

Horizon Wall Panels - Smooth

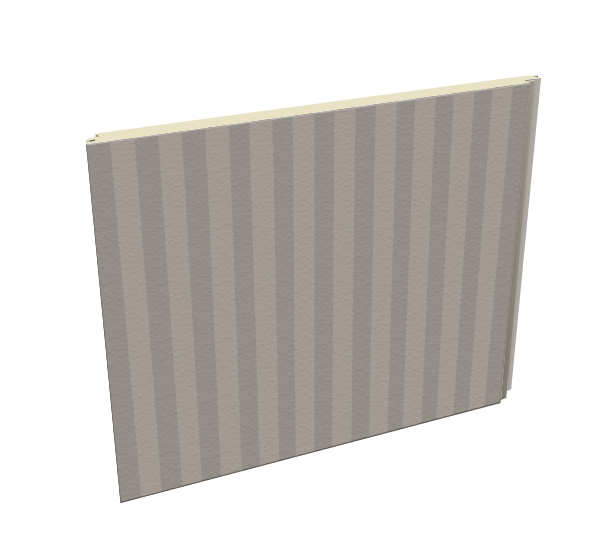

Horizon Wall Panels - Embossed

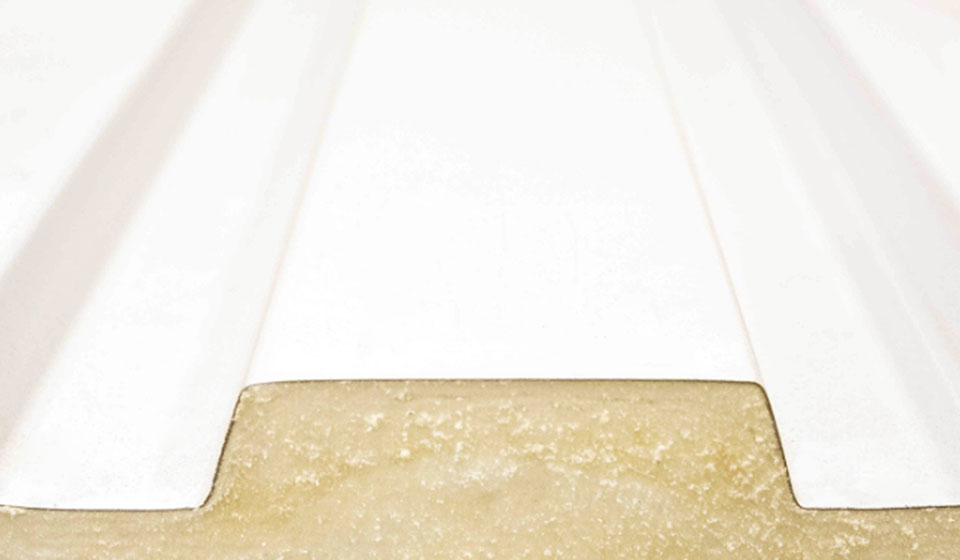

Horizon Wall panels are produced with a standard Mesa profiled steel face with a Smooth (SM) or Light Embossed finish (LE). Provides economical panels for industrial and commercial walls with added strength from a double Mesa profile for long panel lengths.

- COVERAGE WIDTH: 42” (1067mm)

- PANEL LENGTHS: 8’ to 52’ (2438mm to 15850mm)

- PROFILE: Mesa

- EXTERIOR FACE: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

- INTERIOR FACE: 22ga, 24ga, or 26ga galvanized G-90 (Z275) pre-painted steel

- AVAILABLE FINISH: Smooth, Light Emboss

| THICKNESS | 2” | 3” | 4” | 5” | 6” |

| EFFECTIVE R-VALUE* | 16.67 | 25 | 33.33 | 41.67 | 50 |

INTERIOR FACE 26ga Mesa profile in smooth or light embossed galvanized G-90 (Z275) pre painted steel in Regal White. Other gauge options available.

* Thermal testing in accordance with ASTM C1363 and ASTM C518.Standard Exterior Colours

Premium Exterior Colours

- Colours may not appear exactly as shown above and may vary slightly.

- Please confirm prior to specifying, estimating or ordering.

- Final colour selection should be made from a steel colour sample.

- Colour selection may be subject to availability.

- Custom colours available upon request.

Series: Edge, Horizon.

Profile: Mesa or Smooth.

Gauge: 26 ga or heavier.

Finished: Embossed or Smooth.

| Panel Thickness | Design Criteria | 4' Allowable Loads (PSF) | 5' Allowable Loads (PSF) | 6' Allowable Loads (PSF) | 7' Allowable Loads (PSF) | 8' Allowable Loads (PSF) | 9' Allowable Loads (PSF) | 10' Allowable Loads (PSF) | 11' Allowable Loads (PSF) | 12' Allowable Loads (PSF) | 13' Allowable Loads (PSF) | 14' Allowable Loads (PSF) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 2" Thick (See Table Note #3) |

Bending/Shear | 93 | 59 | 41 | 30 | 23 | 18 | 15 | 12 | 10 | ||

| 2" Thick | Deflection (L/180) | 47 | 41 | 33 | 27 | 22 | 19 | 16 | 14 | 12 | ||

| 2" Thick | Connection | 42 | 35 | 33 | 26 | 22 | 19 | 16 | 15 | 13 | ||

| 3" Thick | Bending/Shear | 126 | 101 | 84 | 68 | 52 | 41 | 33 | 27 | 23 | ||

| 3" Thick | Deflection (L/180) | 94 | 77 | 68 | 58 | 34 | 32 | 29 | 19 | 17 | ||

| 3" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | ||

| 4" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 4" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 4" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 5" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 5" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 5" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

| 6" Thick | Bending/Shear | 168 | 134 | 112 | 84 | 64 | 51 | 41 | 34 | 29 | 24 | 21 |

| 6" Thick | Deflection (L/180) | 110 | 101 | 92 | 79 | 67 | 57 | 49 | 42 | 37 | 32 | 29 |

| 6" Thick | Connection | 57 | 45 | 38 | 33 | 29 | 25 | 23 | 20 | 19 | 17 | 16 |

TABLE NOTES:

1) Allowable loads were derived from tests conducted in accordance with ASTM E1592 and ASTM E72.

2) Allowable loads are calculated with a factor of safety of 2.0 for bending and shear.

3) Connection strengths reflect a standard fastener pattern - with two (2) 1/4" - 14 self drilling screw into minimum 14ga substrate. Other substrates must be designed separately. 2" wall panel utilize a flat clip. All other thicknesses utilize an angle clip.

4) Fastener capacity is based on manufacturer pullout/pullover data and are calculated with a safety factor of 3.0.

5) Allowable loads assume a minimum bearing of 2".

6) Thermal Effects were not considered in analysis.

7) The structural capacity of the supporting members were not considered.

8) Bending/Shear and Deflection for 5" and 6" panels based on 4" capacity.

PANEL WEIGHTS (PSF)

| Panel Thickness (in.) |

Panel Width (in.) |

26/26 Steel Gauge (Facer/Liner) | 24/26 Steel Gauge (Facer/Liner) | 22/26 Steel Gauge (Facer/Liner) | 26/24 Steel Gauge (Facer/Liner) | 24/24 Steel Gauge (Facer/Liner) | 22/24 Steel Gauge (Facer/Liner) | 26/22 Steel Gauge (Facer/Liner) | 24/22 Steel Gauge (Facer/Liner) | 22/22 Steel Gauge (Facer/Liner) |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 2.23 | 2.48 | 2.73 | 2.48 | 2.73 | 2.98 | 2.76 | 2.98 | 3.23 |

| 3 | 42 | 2.44 | 2.69 | 2.94 | 2.69 | 2.94 | 3.19 | 2.94 | 3.19 | 3.44 |

| 4 | 42 | 2.65 | 2.90 | 3.15 | 2.90 | 3.15 | 3.40 | 3.15 | 3.40 | 3.65 |

| 5 | 42 | 2.85 | 3.10 | 3.35 | 3.10 | 3.35 | 3.60 | 3.35 | 3.60 | 3.85 |

| 6 | 42 | 3.06 | 3.31 | 3.56 | 3.31 | 3.56 | 3.81 | 3.56 | 3.81 | 4.06 |

MAXIMUM PANEL LENGTHS BASED ON COLOUR (FT).

| Panel Thickness (in.) | Panel Width (in.) | Light Edge 22ga Wall* | Medium Edge 22ga Wall* | Dark Edge 22ga Wall* | Light Horizon 26ga/26ga Wall | Medium Horizon 26ga/26ga Wall | Dark Horizon 26ga/26ga Wall | Light Skyline 24ga/26ga Roof | Medium Skyline 24ga/26ga Roof | Dark Skyline 24ga/26ga Roof |

|---|---|---|---|---|---|---|---|---|---|---|

| 2 | 42 | 25' | 25' | 20' | 38' | 25' | 16' | 47' | 36' | 24' |

| 3 | 42 | 30' | 30' | 20' | 45' | 35' | 25' | 50' | 38' | 30' |

| 4 | 42 | 30' | 30' | 25' | 50' | 38' | 28' | 52' | 41' | 32' |

| 5 | 42 | 32' | 30' | 25' | 52' | 41' | 30' | 52' | 44' | 34' |

| 6 | 42 | 32' | 30' | 25' | 52' | 44' | 32' | 52' | 47' | 36' |

*Smooth or Embossed

Light = Regal White

Medium = Sierra Tan, Parchment, Silver Metallic

Dark = All others

Based on 5' support spacing for walls & 4' support spacing for roofs

*Smooth or Embossed

Subject to change without notice. Please refer to our website, www.artspaninc.com for current information.

ARTSPAN Insulated Metal Panel Test Results Rev 3. (Download File)

Panel Load Table, Weights & Max Lengths Rev 3. (Download File)

Artspan Insulated Metal Panel Brochure Rev 3. (Download File)

IMP Wall Standard Details (Download File)

Horizon Data Sheet (Download File)

IMP Horizon Wall Guide Specification (Download File)

IMP Horizon Wall Guide Specification (Download Editable File)

Panel Dimensions

Panel Features

Weight of aproximately 3.3 lbs/sq.ft. (based of 24ga top and bottom sheets)

5” polyisocyanurate foam core with density of aproximately 2.5 lbs./cu.ft.

Effective R-Value 28.5

Flame Spread Rating (tested in accordance with CAN/ULC S102-10) – 10

Smoke Developed Classification (tested in accordance with CAN/ULC S102-10) – 215

Pre painted galvalume top and bottom steel sheets

Wide selection of colour options available

Patented one piece, continuous corner

Foam-to-foam bond panel joints

Pre finished on exterior and interior sides

High rib profile accommodates mechanical lines

STC Rating (tested in accordance with ASTM E90 standard) – 26

Summit Structural Panels Gallery

Interior Face

- 24 Gauge Deep Corrugated pre-painted, galvanized, or galvalume steel Grade 33

- Deep corrugation contributes to self-framing characteristics of panel system

- Can be left unfinished or drywall and other inferior finishing can be attached directly to the steel face

- Deep corrugation provides chase for electrical and mechanical components

Exterior Face

- 24 gauge, light corrugated pre-painted Grade 33 steel

- Conforms to ASTM A792, Z275 or AZM150 finish

- Clean, maintenance free exterior finish

- No exposed fasteners or panel joints

- Wide variety of colours available

Pre-Cut, Flat-Packed Packages

- Summit Panels can be used to form the floor, wall and roof pf your project

- Panels can come pre-cut to the required length and pitch

- Packages can include the required fasteners, sealants and hardware required to assemble your building shell

Assembly Drawings

- Each panel is labelled and corresponds with a detailed assembly drawing.

- Stamped engineered structural drawings can be provided

- A detailed assembly guide is provided